Laser kuchenesa uye pickling nzira mbiri dzakasiyana pakurapa simbi pamusoro.Laser kuchenesa isimbi pamusoro pekurapa maitiro ayo anoshandisa laser danda rinoburitswa nelaser jenareta kuburitsa simba rakawanda kubvisa ngura, kubvisa pendi, uye kubvisa machira.Pickling inzira yekurapa inoshandiswa kubvisa ngura, mavara, tsvina, kana zvinosvibisa kubva pamusoro pesimbi.

Pickling

Pepa rekunhonga rakagadzirwa nepamusoro-soro rinopisa-rakakungurutswa pepa seyakabikwa, uye iyo oxide layer inobviswa neiyo pickling unit, yakatemwa, uye yapera.Chigadzirwa chepakati pakati pemahwendefa, pachigadziro chekuve nechokwadi chemhando yepamusoro uye zvinodiwa zvekushandisa, zvinoita kuti vashandisi vakwanise kudzikisa mutengo wekutenga.

Pickling Sheets Advantages

1. Unhu hwepamusoro hwakanaka, nokuti simbi yesimbi oxide scale inobviswa kubva kune inopisa-yakaputirwa pickling ndiro, iyo inovandudza kunaka kwepamusoro yesimbi uye inofambisa welding, mafuta uye kupenda.

2. Kururamisa kwepamusoro-soro, mushure mekugadzirisa, chimiro cheplate chinogona kuchinjwa kune imwe nhanho, nokudaro kuderedza kutsauka kwekusaenzana.

3. Inovandudza kupera kwepamusoro uye inosimudzira chitarisiko.

Applications

Zvinogona kutaurwa kuti pickling sheet chigadzirwa chinodhura pakati pekutonhora-yakaputirwa pepa uye inopisa-yakaputirwa pepa.Iyo ine huwandu hwakasiyana hwekushandisa muindasitiri yemotokari, indasitiri yemuchina, mwenje maindasitiri midziyo uye zvidhindo zvikamu zveakasiyana maumbirwo, senge matanda, sub-matanda, marimu, spokes, mapaneru engoro, mafeni, madhiramu emafuta emakemikari, pombi dzakasungwa, magetsi. makabati, fenzi, Iron ladders, nezvimwewo, zvine tarisiro yemusika wakakura.Pazasi isu tichasuma iyo tekinoroji maitiro ekutora pickling.

Pickling Principle

Pickling chirongwa chepamusoro chinoshandisa mushonga weasidhi kubvisa chikero uye ngura pamusoro pesimbi, kazhinji pamwe chete nekufanopfura.Kazhinji, workpiece inonyudzwa mumushonga wemakemikari senge sulfuric acid kubvisa oxides nemamwe mafirimu pamusoro pesimbi, inova pre-kurapa kana yepakati kurapwa kwe electroplating, enamel, rolling uye mamwe maitiro.Iyo inozivikanwawo sewet cleaning.

Iyo pickling maitiro anonyanya kusanganisira yekunyudza pickling nzira, kupfapfaidza pickling nzira uye acid paste ngura yekubvisa nzira.

Maasidhi anoshandiswa anowanzo sulfuric acid, hydrochloric acid, phosphoric acid, nitric acid, chromic acid, hydrofluoric acid uye yakasanganiswa asidhi.

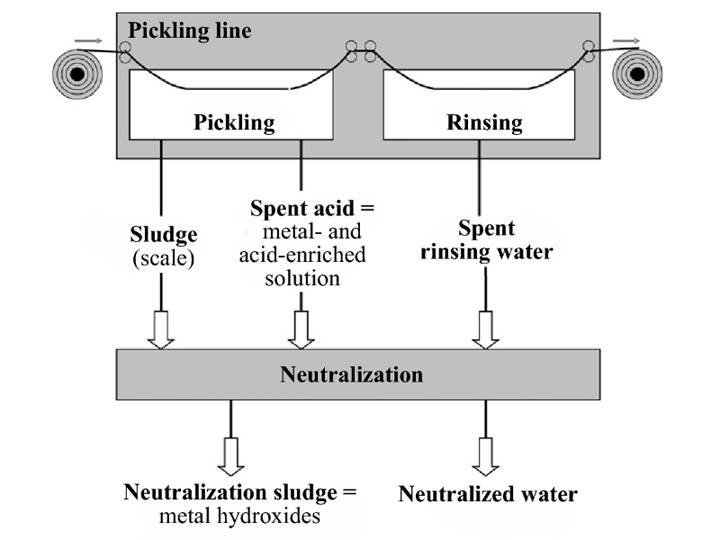

Process Flow

Kurembera pazvikamu zvesimbi → kucheneruka kwekemikari (kubvisa kemikari yealkaline yakajairwa kana kuti surfactant degreasing) → kugeza mvura inopisa → kugeza mvura inoyerera → danho rekutanga rekunhonga → Kugeza mvura inoyerera → Danho repiri kunhonga → kugeza mvura inoyerera → endesa kune imwe nzira (yakadaro se: kuisa ruvara rwemakemikari → kudzokorodza → kugeza mvura yemupombi → kuomesa mishonga → Kugeza → Kuvhara Kurapa → Kugeza → Kuomesa → Kwapera).

Common Defects

Iron oxide scale intrusion: Iron oxide scale intrusion is a surface defect inoumbwa panguva inopisa inopisa.Mushure mekunhonga, inowanzo kudzvanywa muchimiro chemavara matema uye mitsetse, iyo nzvimbo ine hutsinye, kazhinji ine ruoko inonzwa, uye inoratidzika zvishoma nezvishoma kana zvakanyanya.Iyo inowanzo kukonzerwa nekusakwana kwekupisa maitiro, descaling process uye rolling process ye pickling.

Oxygen spot (padenga landscape paint): inoreva chitarisiko-chakaita dot, mutsara kana gomba-chakasiiwa mushure mekunge chiyero che iron oxide chiri pamusoro pesimbi inopisa-yakakungurutswa yagezwa.Kukunguruka kunotsikirirwa mukati me matrix, iyo inosimbiswa mushure mekunhonga.Iyo ine imwe mhedzisiro pakuonekwa, asi haina kukanganisa kuita.

Macular: mavara eyero anoonekwa pane chikamu kana bhodhi rose pamusoro, risingagoni kuvharwa mushure mekuzora mafuta, izvo zvinokanganisa kunaka uye kutaridzika kwechigadzirwa.Chikonzero chikuru ndechekuti basa repamusoro remutsetse uchangobva mutangi rekunhonga rakakwira, mvura yekugezesa inotadza kugeza tambo zvakanaka, danda rekupfapfaidza nemuromo wetangi rekusuka zvakavharika, uye makona haana kuenzana.

Under-pickling: Kumusoro kwesimbi yemutsetse kune zvikero zve iron oxide zvemuno zvisina kucheneswa uye zvisina kukwana kubviswa, uye plate pamusoro ipfumbu-dema, ine makwande ehove kana kuyerera kwemvura kwakachinjika.Iine chekuita nekuita kweasidhi, zvakanyanya nekuti iyo acid yekumisikidza haina kukwana, tembiricha haina kukwirira, tambo inomhanya zvakanyanya, uye tambo haigone kunyudzwa muasidhi.

Kunyanya-kunhonga: Pamusoro pesimbi yemutsetse inowanzo sviba dema kana shava dema, ichiratidza bhuroko, mavara matema anotsemuka kana macular, uye pamusoro peplate inowanzoita hutsinye.Chikonzero chakapesana nekunyura pasi.

Kusvibiswa Kwezvakatipoteredza

Izvo zvinosvibisa zvakanyanya mukugadzira nzira ndeyekuchenesa mvura yetsvina inogadzirwa nekugezwa kwemvura pamatanho ese, guruva rinogadzirwa nejecha rekuputika, iyo hydrogen chloride acid mhute inogadzirwa nepickling process, uye tsvina inogadzirwa ne pickling, rinsing. phosphating, neutralization uye maitiro ekudzivirira ngura.Tangi mvura, tsvina inosara, tsvina sefa element, mbishi madhiramu asina chinhu uye marara ekurongedza, etc. Izvo zvakanyanya zvinosvibisa ihydrogen chloride, pH, SS, COD, BOD?, ammonia nitrogen, petroleum, nezvimwe.

Laser Kuchenesa

Kuchenesa Musimboti

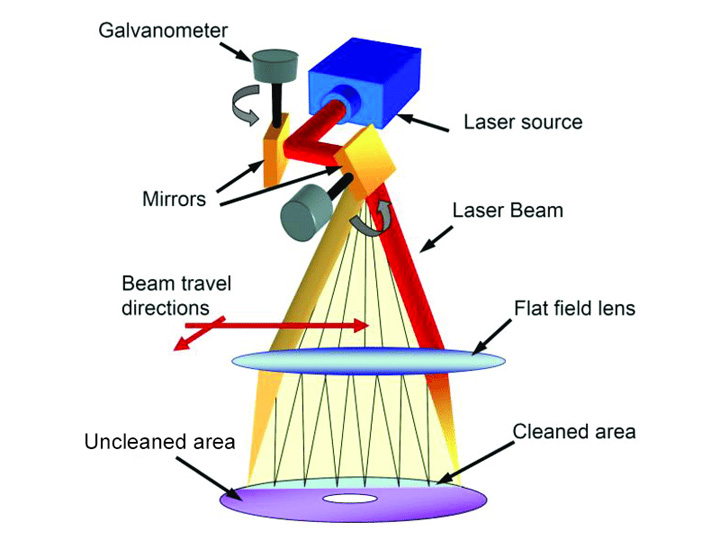

Laser yekuchenesa muchinakushandisa laser simba kupinda pamusoro pechinhu.Maerekitironi ari muchinhu anotora kuzunguzika kwesimba kweanenge 100 femtoseconds, uye anogadzira plasma pamusoro pechinhu.Mushure me7-10 picoseconds, simba re electron rinoendeswa kune reti uye latisi inotanga kubvunda.Mushure meiyo picosecond, chinhu chinotanga kugadzira tembiricha yakakura, uye zvinhu zvemuno zvakarutswa nelaser zvinotanga kupisa, kunyungudika uye kunyungudika, kuitira kuti uwane chinangwa chekuchenesa.

Kuchenesa Maitiro & Mhedzisiro

Kuenzaniswa neyekunhonga nzira, iyo laser yekuchenesa sisitimu iri nyore kwazvo, hapana pretreatment inodikanwa, uye basa rekuchenesa rekubvisa mafuta, oxide layer kubviswa uye kubviswa ngura kunogona kuitwa panguva imwe chete.Ingobatidza mudziyo kuti uburitse mwenje, wobva wauchenesa.

Laser yekuchenesa sisitimu inogona kusvika yakakwira indasitiri yekuchenesa nhanho yeSa3 level, inenge isina kukuvadza kune kuoma, hydrophilicity uye hydrophobicity yechinhu chepamusoro.Inonyatsoita kupfuura pickling.

Zvayakanakira nezvayakaipira

Process Flow uye Operation Zvinodiwa

Kuenzaniswa neyekunhonga chishandiso ine anopfuura gumi nemaviri maitiro, laser yekuchenesa yakawana yakareruka maitiro uye yakanyatso yawana nhanho imwe.Zvikuru zvinopfupisa nguva yekuchenesa uye kurasikirwa kwezvinhu.

Iyo pickling nzira ine zvakaomesesa zvinodiwa pakuita basa: iyo workpiece inofanira kunge yakanyatso degreasing kuve nechokwadi chemhando yekubvisa ngura;iyo yekusangana kwepickling solution inodzorwa kudzivirira iyo workpiece kubva pakusvibiswa nekuda kwekunyanya kuwanda kweasidhi;tembiricha inodzorwa zvinoenderana nemaitiro ekugadzirisa kudzivirira kukanganisa kune workpiece uye Iyo midziyo inokonzera ngura;iyo pickling tangi zvishoma nezvishoma inoisa sludge, iyo inovhara pombi yekudziya uye mamwe maturusi ekudzora, uye inoda kubviswa nguva dzose;uyezve, zvinofanirwa kutarisisa kunguva yepickling, kudzvanywa kwejekiseni, kuvhiya kuvhiya, midziyo yekupedza, nezvimwe.

Laser yekuchenesa inogona kuona benzi-sekuvhiya kana kutoita otomatiki isina kurongeka mushure mekugadzika paramita padanho rekutanga.

Cleaning Effect uye Environmental Kusvibisa

Pamusoro peiyo yakasimba yekuchenesa maitiro, laser yekuchenesa sisitimu zvakare ine mukana wehukuru hwekutadza kushivirira.

Oxygen macular, redness uye blackening inowanzoitika nekuda kwekukanganisa mukushanda kwepickling nzira, uye chiyero chekuramba chakakwirira.

Iyo mvura inodonhedza laser kuyedza inoratidza kuti kunyangwe iyo laser yekuchenesa yakakwirisa, ichine yakasimba simbi inopenya, uye haiburitse hydroxide nezvimwe zvinosvibisa, izvo zvisingazokanganisa nzira dzinotevera dzekugadzirisa senge welding.

Pachave pasina kusvibiswa kwezvakatipoteredza senge tsvina yemvura uye slag mukuita kwese kwelaser yekuchenesa, iyo ndiyo yakasvibira yekuchenesa nzira.

Chikamu Mutengo VS Shanduko Mutengo

Chishandiso chekunhonga chinoda makemikari sezvinhu zvinodyiwa, saka mutengo weyuniti unosanganisira kudzikira kwemidziyo + mutengo wekushandisa.

Laser yekuchenesa muchina inoda hapana chinodyiwa kunze kwekutenga michina.Mari yeyuniti ndiyo kudzikira kwemidziyo.

Naizvozvo, iyo yakakura chiyero chekuchenesa uye kureba kwemakore, inodzikira mutengo weyuniti yekuchenesa laser.

Kuumbwa kwemutsara wekugadzira pickling kunoda maitiro akaoma, uye chiyero che pickling agents kune zvakasiyana-siyana zvesimbi hazvina kufanana, saka mutsara wekugadzira wekushandura unoda mutengo mukuru wekushandura, uye zvinhu zvesimbi zvinofanira kucheneswa munguva pfupi. haana kuroora uye haagone kuchinjika.

Iko hakuna mutengo wekushandura wekuchenesa laser: mushure mekushandura maparamita esoftware yemuchina wakafanana wekuchenesa, mhedzisiro yekuchenesa ndiro yesimbi miniti imwe uye aluminium alloy miniti inotevera inogona kuwanikwa.Zvakanakira mabhizinesi kuita JIT inoshanduka kugadzirwa.

Pfupisa

Pickling ndiro ine huwandu hwakasiyana uye hwakadzama application mukugadzira kugadzira, uye inoita basa rakanaka mukutsigirwa kwemaindasitiri.Nekudaro, nekuenderera mberi kukwidziridzwa kweindasitiri yekugadzira, kugona kugona uye kugadzirisa kwemaitiro kuri kuitwawo zvishoma nezvishoma.

Nekusimudzirwa kwekuziva kwevanhu kwezvakatipoteredza, hurumende nemabhizinesi vari kuwedzera kuomesera mitsara yekugadzira mitsara, uye mibairo yemabhizinesi ane hukama iri kuramba ichionda uye kutetepa.Iyo yese nharaunda yakanakira yekuchenesa laser.

Zvichida mumakore gumi anotevera, mapepa ekunhonga achava nezita idzva - laser yekuchenesa mapepa.